REFRIGERATOR FILTER DRIER is an indispensable key component in the refrigeration cycle system. Its main function is to efficiently remove impurities, moisture and acidic substances in the refrigerant to ensure the efficient operation of the refrigeration system. Through precise filtering and drying mechanisms, it can effectively prevent these harmful substances from damaging key components such as the compressor, expansion valve, condenser and evaporator, and ensure the stability and performance of the entire refrigeration system.

1. Product Features

(1) High-efficiency molecular sieve drying technology

The high-quality molecular sieve is used as the drying medium, which has a strong adsorption capacity and can deeply remove moisture and acidic substances in the refrigerant. The molecular sieve has a large adsorption capacity and high drying efficiency, ensuring that the purity and performance of the refrigerant are not affected. At the same time, the molecular sieve has good chemical stability and can work stably for a long time under harsh working conditions, ensuring the continuity and reliability of the drying effect.

(2) Accurate filtration of impurities

The filter dryer is equipped with a fine filtering device that can effectively intercept impurity particles such as metal chips, welding slag, and oil stains in the refrigerant. If these impurities enter the refrigeration system, they may cause valve blockage, component wear and other problems, seriously affecting the normal operation of the system. Through multi-level filtering design, it is ensured that only pure refrigerant circulates in the system, improving the operating efficiency and reliability of the system.

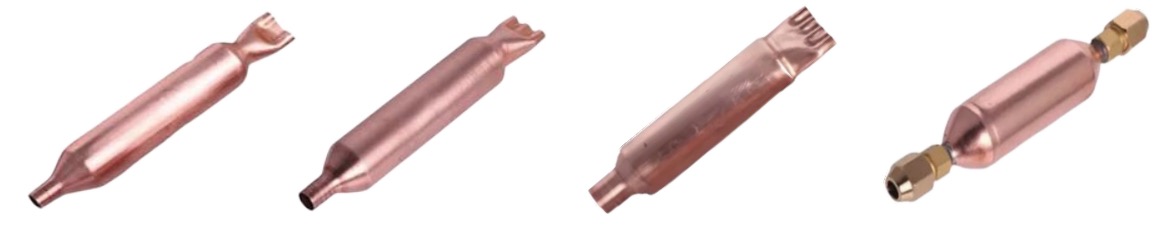

(3) Sturdy and durable structural design

The product uses high-quality copper as the main material, which has good thermal conductivity and corrosion resistance, and can adapt to various working conditions in the refrigeration system. At the same time, the structure of the filter dryer is reasonably designed, the connection parts are firm and reliable, and can withstand certain pressure and temperature changes, ensuring stability and safety in harsh environments such as high pressure and high temperature. The yellow protective cap not only serves as a decoration, but also effectively prevents damage to the connection port during installation and transportation.

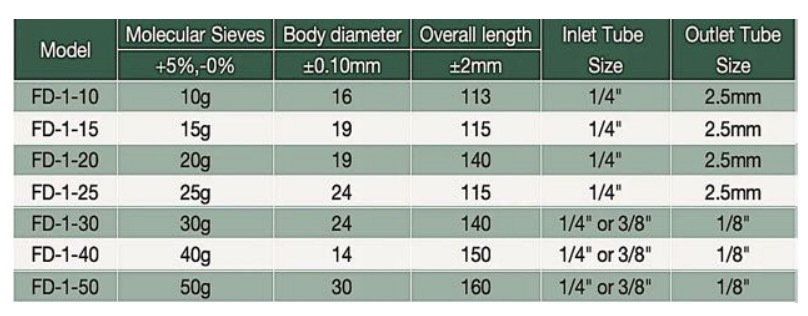

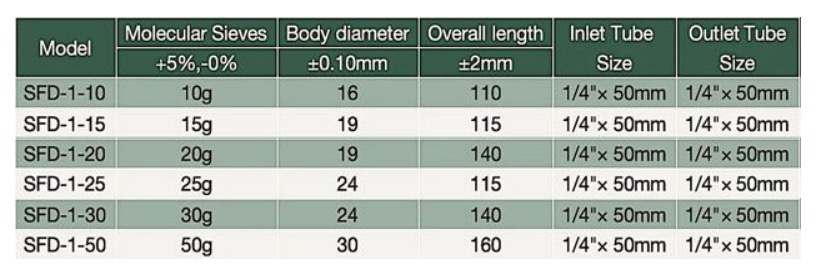

2. Technical parameters

3. Application scenarios

Widely used in various refrigeration systems, including but not limited to:

Household refrigerators and freezers: ensure the long-term stable operation of the refrigeration system, extend the service life, and prevent failures caused by the accumulation of impurities and moisture.

Commercial refrigeration equipment: such as supermarket freezers, ice cream display cabinets, etc., to ensure that the refrigeration system can work efficiently and reliably under high-load operating conditions to meet the needs of commercial operations.

Industrial refrigeration system: In the freezing and refrigeration processes of the chemical, pharmaceutical, and food processing industries, filter dryers can effectively protect expensive refrigeration equipment and improve production efficiency and product quality.

Air conditioning system: Whether it is a household air conditioner or a central air conditioning system, the filter dryer can remove impurities and moisture from the refrigerant, ensure the cooling effect and energy efficiency of the air conditioner, and reduce maintenance costs.

4. Installation and maintenance recommendations

(1) Pre-installation inspection

Before installing the filter dryer, be sure to carefully check the appearance of the product to ensure that there is no damage, deformation, or other problems. At the same time, check whether the model specifications meet the design requirements to avoid installation difficulties or system operation failures caused by inconsistent specifications. Check whether the inlet and outlet pipe diameters match the system pipes to ensure the accuracy and sealing of the connection.

(2) Correct installation position

The filter dryer should be installed in a suitable position in the refrigeration system, usually between the condenser and the expansion valve, or the specific installation position can be determined according to the system design requirements. Ensure that the installation location is convenient for operation, maintenance, and inspection, and avoid being affected by external environmental factors (such as high temperature, humidity, vibration, etc.) to ensure its normal operating performance.

(3) Connection operation

When connecting the filter dryer to the system pipeline, ensure that the connection parts are clean and dry, and use appropriate sealing materials (such as sealing tape or sealant) for sealing to prevent refrigerant leakage. According to the system design requirements and pipeline connection standards, use appropriate connection methods (such as welding, threaded connection, etc.) for installation to ensure the firmness and reliability of the connection. For welding connections, pay attention to controlling the welding temperature and time to avoid damage to the filter dryer body.

(4) Regular inspection and replacement

During the operation of the refrigeration system, the filter dryer should be inspected regularly, focusing on the inlet and outlet pressure difference and whether there are signs of leakage on the appearance. If the pressure difference is too large or leakage is found, timely measures should be taken to repair or replace it. Generally speaking, it is recommended to regularly replace consumables such as molecular sieves and filter elements according to the system's operating time and operating conditions to ensure the drying and filtering effect of the filter dryer and ensure the long-term stable operation of the refrigeration system.