The condenser is a key component in the refrigeration system, responsible for converting high-temperature and high-pressure gaseous refrigerant into liquid state while releasing heat to the environment. These condensers are suitable for various commercial and industrial refrigeration systems.

1. Product Features

Efficient heat dissipation: adopts a large-area heat exchange design to ensure efficient heat exchange efficiency.

Durability: Made of high-quality materials, it has good corrosion resistance and durability.

Low noise: The design is optimized to reduce noise during operation and is suitable for various application environments.

Easy maintenance: The structural design takes into account the convenience of maintenance, which is convenient for regular cleaning and inspection.

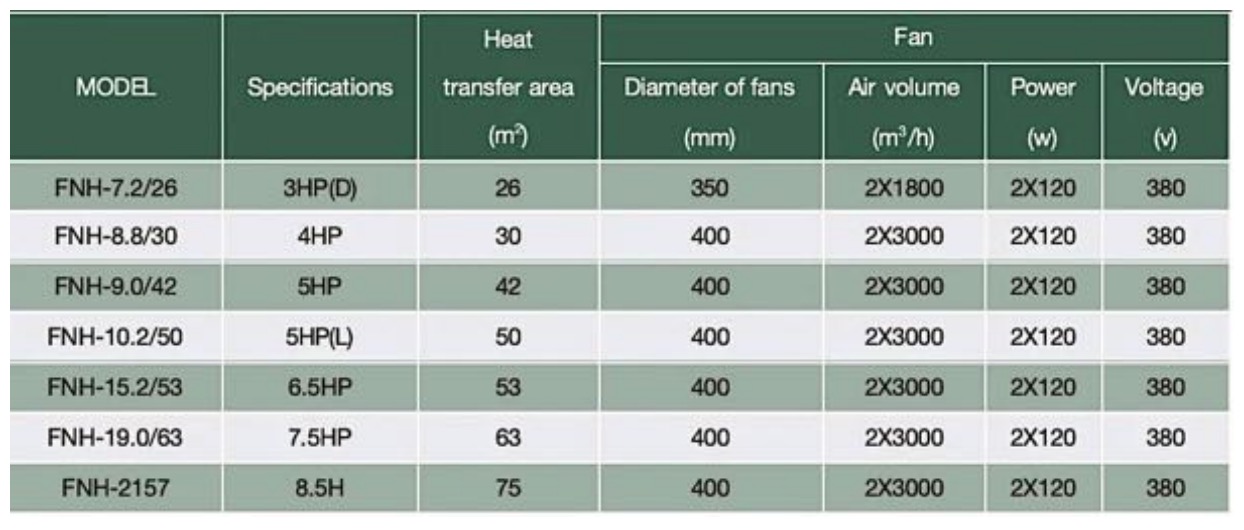

2. Technical parameters

3. Maintenance and care

Clean the outside and inside of the condenser regularly to ensure good heat dissipation.

Check the refrigerant flow of the condenser to ensure that there is no blockage or leakage.

Check the operating status of the fan and motor regularly, and replace or repair them if necessary.