BALL VALVE is a commonly used fluid control device that controls the flow of fluid by rotating a ball with a through hole. Ball valves are widely used in various industrial fields, including but not limited to water treatment, chemical industry, petroleum, natural gas, food processing, etc. The following are some typical features and functions of ball valves:

Easy operation: By rotating the handle or actuator, you can easily open or close the valve to control the flow of fluid.

Quick opening and closing: The ball valve can quickly switch between the fully open or fully closed position, and the opening and closing speed is fast.

Good sealing performance: The sealing surface of the ball valve is usually made of materials such as polytetrafluoroethylene (PTFE), which has good sealing performance and can effectively prevent leakage.

Low fluid resistance: Since the flow channel of the ball valve is straight, the resistance when the fluid passes through is small, which is suitable for high flow applications.

Bidirectional flow: The ball valve allows the fluid to flow in both directions and is suitable for occasions requiring bidirectional control.

Easy maintenance: The ball valve has a simple structure and is easy to disassemble and maintain.

Durability: The ball and valve seat of the ball valve are usually made of corrosion-resistant materials such as stainless steel and copper alloy, with good durability and corrosion resistance.

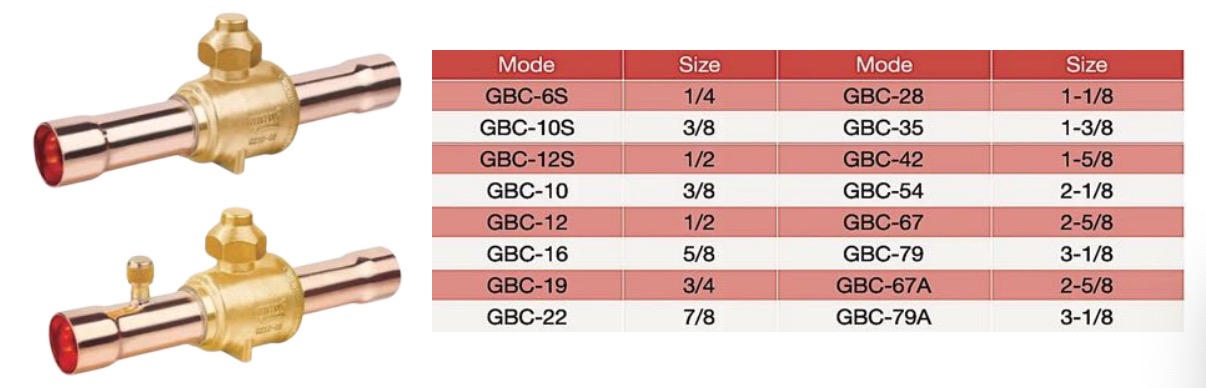

Various sizes and models: Ball valves are available in a variety of sizes and models to suit different pipe diameters and fluid characteristics.