DCL FILTER DRIER is a component commonly used in refrigeration systems. Its main function is to remove moisture and impurities in the system to prevent refrigerant contamination, thereby protecting the normal operation of the system and extending the life of the equipment. The following is a product introduction to DCL FILTER DRIER:

1. Product Overview

DCL FILTER DRIER is a filter designed for refrigeration systems. It can filter out moisture, acid, and other contaminants in the system to ensure the purity of the refrigerant and improve system efficiency.

2. Product Features

Material: Usually made of high-quality metals (such as copper or aluminum) and chemically resistant materials.

Filter media: Contains a desiccant such as a molecular sieve or desiccant to absorb moisture.

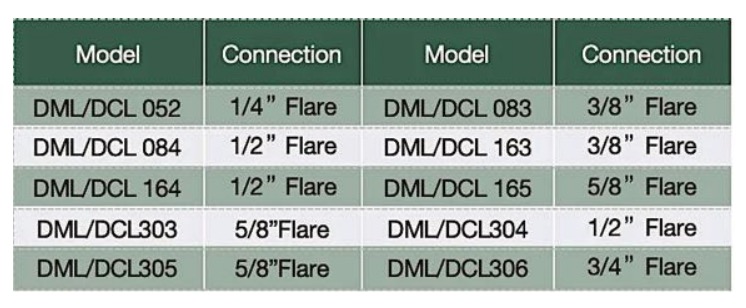

Interface type: Depending on the model, different interface types may be equipped, such as 1/4" Flare, 1/2" Flare, 3/8" Flare, etc., to meet different system requirements.

Compatibility: Applicable to a variety of refrigerants, including but not limited to R134a, R410A, etc.

3. Scope of application

Application scenarios: Widely used in refrigeration systems such as automotive air conditioners, commercial refrigeration equipment, and household refrigerators.

Fluid type: Applicable to a variety of refrigerants.

4. Usage method

Installation: Install the filter drier at the appropriate location in the refrigeration system, usually between the condenser and the expansion valve.

Maintenance: Check the filter regularly and replace the desiccant or the entire filter if necessary.

5. Precautions

Ensure the system is clean before installation to avoid contamination.

Check the pressure drop of the filter regularly to evaluate the filtering effect.

Avoid direct sunlight and extreme temperatures when storing.