Expansion Valve ORIFICE, also often called orifice valve or fixed-orifice expansion valve, is a device used in refrigeration systems that limits and controls the flow of refrigerant into the evaporator through a fixed-size orifice. This type of expansion valve is suitable for some simple refrigeration systems where the requirements for flow control are not particularly strict. Here are some basic features and product descriptions of ORIFICE expansion valves:

Fixed orifice: Unlike adjustable thermal expansion valves, the aperture of ORIFICE expansion valves is fixed, which means that it cannot adjust the flow rate according to changes in system demand.

Simple structure: Since there is no complex temperature sensing package or adjustment mechanism, the structure of ORIFICE expansion valve is relatively simple and the cost is low.

Easy to install: This type of expansion valve is usually easy to install and does not require a complicated debugging process.

Easy maintenance: Due to its simple structure, the maintenance and cleaning of ORIFICE expansion valves are also relatively easy.

Applicability: It is suitable for some small or simple refrigeration systems, such as household air conditioners, small cold storage, etc.

Flow restriction: The flow of refrigerant is restricted by a fixed orifice to prevent too much refrigerant from entering the evaporator, thereby avoiding compressor overload.

Materials: Usually made of corrosion-resistant materials such as brass or stainless steel to adapt to different refrigerants and working environments.

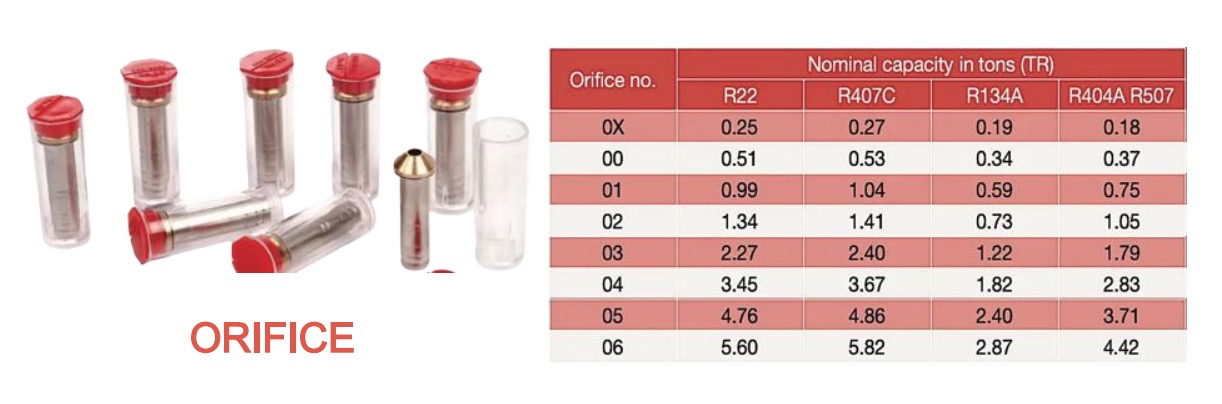

Model diversity: A variety of models and specifications are available to adapt to different refrigerant types and system requirements.

Technical data: Provide detailed technical data, including rated flow, applicable refrigerant type, working pressure range, etc.