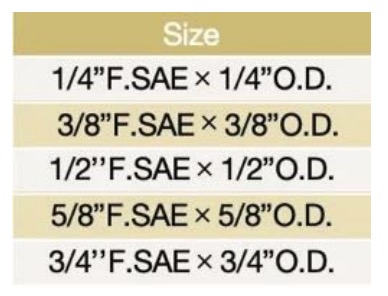

1. Appearance and Material

FLARE NUT nuts present a typical hexagonal shape, with six flat and even protrusions on the edge, which is convenient for rotation and tightening with a wrench or pliers. The surface of the nut is golden, showing the natural luster of brass. Although there are some slight wear and traces of use on the surface, this does not affect its overall beauty and practicality.

2. Structure and Features

Hexagonal groove: The outer periphery of the nut is designed with a clear hexagonal groove. This design not only increases the contact area between the nut and the rotating tool, improves the stability during rotation, but also makes it easier for the nut to be screwed in or out of the thread.

Hollow structure: The center part of the nut is shallow, showing its internal hollow structure. This design not only reduces the overall weight of the nut, but also makes the nut more flexible and convenient when connecting or fixing other parts.

Brass material: Made of high-quality brass, it has excellent corrosion resistance and oxidation resistance, and can maintain its performance and appearance in harsh environments.

3. Application scenarios

FLARE NUT nuts are widely used in various industrial, mechanical and automotive fields. It is usually used to connect or fix pipes, valves, mechanical equipment and other parts to ensure that the connection between these parts is firm and reliable. Due to its excellent corrosion resistance and oxidation resistance, FLARE NUT nuts are also suitable for some occasions that need to be exposed to humid or corrosive environments for a long time.

4. Product advantages

High strength: The brass material makes the nut have excellent strength and durability, and can withstand greater pressure and torque.

Easy to install: The hexagonal groove design makes the nut easier to rotate and tighten, reducing the difficulty and time cost of installation.

Corrosion resistance: The brass material has excellent corrosion resistance and oxidation resistance, and can maintain its performance and appearance in harsh environments.

5. Precautions

Before installation, make sure that the nut matches the part to be connected and check whether the thread of the nut is intact.

Use appropriate tools and strength to rotate and tighten to avoid damaging the nut or causing loose connection.

Check the connection status of the nut regularly to ensure that it always maintains good tightness and stability.