A vibration absorber is a device used to reduce or eliminate vibration and noise in a piping system. The following is a detailed description of this product:

1. Product function:

Reducing vibration: Absorbing and reducing vibration in the piping system to prevent vibration from being transmitted to other equipment and structures.

Reducing noise: Reducing noise caused by vibration and improving the operating comfort of the system.

Protecting equipment: Prolonging the service life of the equipment by reducing the damage to the pipeline and related equipment caused by vibration.

Improving system stability: Improving the operating efficiency and reliability of the entire refrigeration or air-conditioning system by stabilizing the pipeline system.

2. Product features:

Design: Usually composed of a metal braided hose and a copper joint, the metal braided hose has good flexibility and pressure resistance.

Material: The metal braided layer is usually made of stainless steel, which is corrosion-resistant and high-temperature resistant; the copper joint is used to connect the pipeline and has good thermal conductivity and sealing.

Interface: The copper joints at both ends can be connected to other pipelines or equipment in the system, usually using threaded connections.

Various sizes: A variety of sizes and lengths are available to meet different system requirements.

3. Product application:

Widely used in refrigeration systems, air conditioning systems, heat pump systems, etc., especially in places where vibration and noise need to be reduced.

It can be installed on the outlet pipes of equipment such as compressors, pumps, fans, etc. to reduce the vibration and noise generated during the operation of these equipment.

4. Product installation:

Usually installed on pipes near the vibration source, such as the outlet pipes of compressors, pumps and other equipment.

It is necessary to install it correctly according to the manufacturer's instructions to ensure the best shock absorption effect.

5. Product maintenance:

Regularly check whether the connection of the vibration absorber is tight and whether the metal braided layer is damaged.

Clean or replace as needed to maintain good shock absorption effect.

6. Technical specifications:

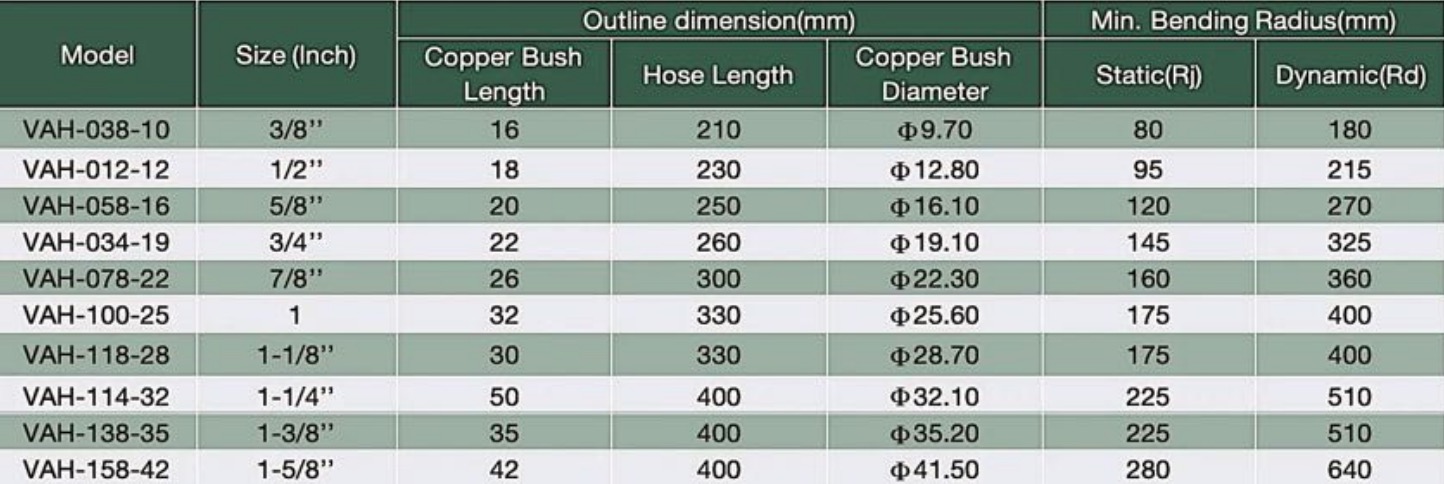

Model: A variety of models are available, such as VAH-038-10, VAH-012-12, VAH-058-16, etc., each model corresponds to different sizes and lengths.

Size: The size is expressed in inches, such as 3/8", 1/2", 5/8", etc., corresponding to different copper connector diameters and hose lengths.

Copper connector length: The length of copper connectors of different models is different, such as 16mm, 18mm, 20mm, etc.

Hose length: The length of hoses of different models is different, such as 210mm, 230mm, 250mm, etc.

Copper connector diameter: The diameter of copper connectors of different models is different, such as Φ9.70mm, Φ12.80mm, Φ16.10mm, etc.

Minimum bending radius: The static and dynamic minimum bending radius are different, such as 80mm/180mm, 95mm/215mm, 120mm/270mm, etc.