A CHECK VALVE is an automatically operated valve that allows fluid to flow in only one direction while preventing reverse flow. Check valves are very important in various industrial and commercial applications, such as in water supply systems, HVAC, refrigeration systems, and various fluid delivery systems. Here are some typical features and functions of check valves:

One-way flow: Check valves ensure that fluid flows in only one direction, preventing backflow, thereby protecting the system from damage.

Automatic operation: Check valves usually do not require external energy to operate, and the pressure difference of the fluid is the driving force for its opening and closing.

Various materials: Check valves can be made of a variety of materials, including plastic, cast iron, copper, stainless steel, etc., to adapt to different fluids and working environments.

Various sizes and models: Check valves are available in a variety of sizes and models to accommodate different pipe diameters and fluid characteristics.

Low pressure loss: A well-designed check valve should have low pressure loss under normal flow conditions.

Easy to install and maintain: Check valves are usually easy to install in pipe systems and have relatively low maintenance requirements.

Reliability: Check valves can provide long-term reliable service when properly selected and installed.

Features:

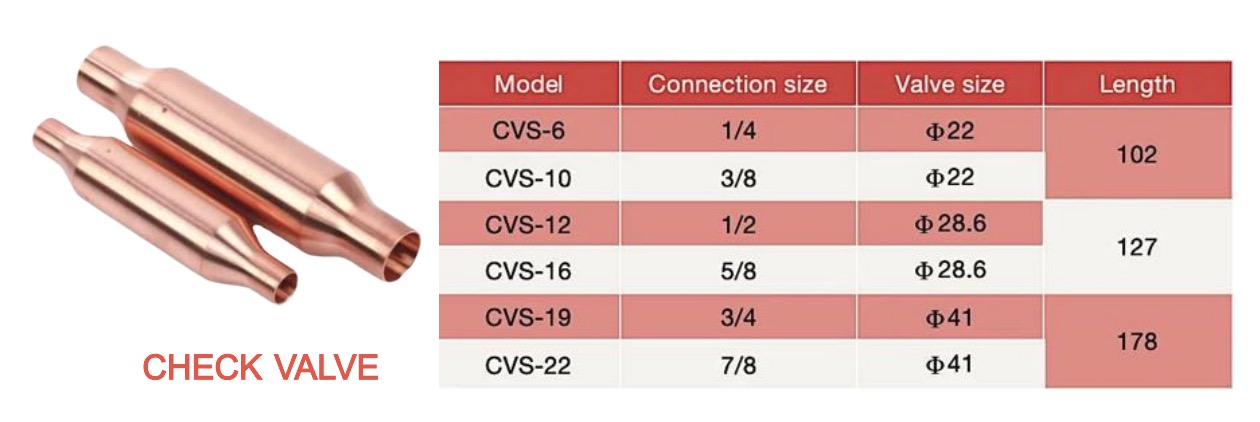

Copper body: The valve body may be made of copper, which has good corrosion and wear resistance.

Multiple connection sizes: A variety of connection sizes (such as 1/4, 3/8, 1/2, etc.) are available to suit different pipeline needs.

Different lengths: Different models of check valves may have different lengths to suit different installation spaces.