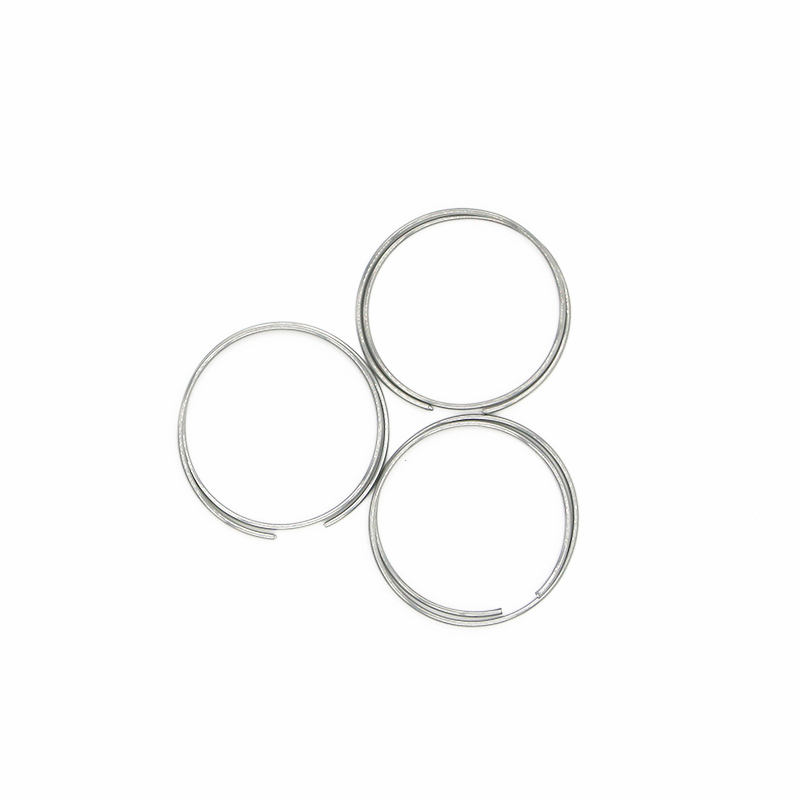

Brazing Alloy is an alloy material used to connect metal parts. It is heated to melt it, then flows into the gap between the metal parts to be connected, and forms a strong connection after cooling. Brazing is a common metal connection technology, widely used in electronics, automobiles, aerospace and other fields.

1. Product Features:

High-strength connection: Brazing Alloy can provide a connection strength close to that of the parent material, ensuring the reliability and durability of the connection.

Good conductivity: Many Brazing Alloys have good conductivity and are suitable for applications that require electrical connections.

Corrosion resistance: Brazing Alloys generally have good corrosion resistance and can maintain the stability of the connection in harsh environments.

Multiple choices: Brazing Alloys are available in a variety of types, including silver-based, copper-based, aluminum-based, etc. The most suitable alloy can be selected according to different application requirements.

Easy to process: Brazing Alloy is generally easy to process and can be easily connected through the heating and cooling process.

2. Usage:

Surface treatment: Before brazing, the surface of the connected parts needs to be cleaned and treated to remove grease and oxides.

Brazing alloy selection: Select the appropriate brazing alloy according to the material and application requirements.

Heating: Heat the connected parts to the melting point of the brazing alloy so that it melts and flows into the gap.

Cooling: Allow the connected parts to cool naturally to form a strong connection.

3. Notes:

The temperature needs to be controlled during the brazing process to avoid overheating and material damage.

Selecting the right brazing alloy is essential to ensure the quality and performance of the connection.

The brazed parts may require post-processing, such as cleaning and inspection, to ensure the quality and reliability of the connection.

The selection and use of BRAZING ALLOY needs to be determined based on the specific application requirements and material properties to ensure the best connection effect.