Horizontal Liquid Receiver is a device used to receive, store and distribute liquid refrigerant in refrigeration systems. The following is a detailed description of this product:

1. Product Function:

Receive liquid refrigerant: Receive liquid refrigerant from the condenser and supply refrigerant to the system when needed.

Store excess refrigerant: Store excess liquid refrigerant when the refrigerant flow exceeds the system demand.

Stabilize system operation: Help maintain stable operation of the system by regulating the supply of refrigerant.

Prevent liquid from entering the compressor: Prevent liquid refrigerant from entering the compressor directly, thereby preventing possible liquid hammer and protecting the compressor from damage.

2. Product Features:

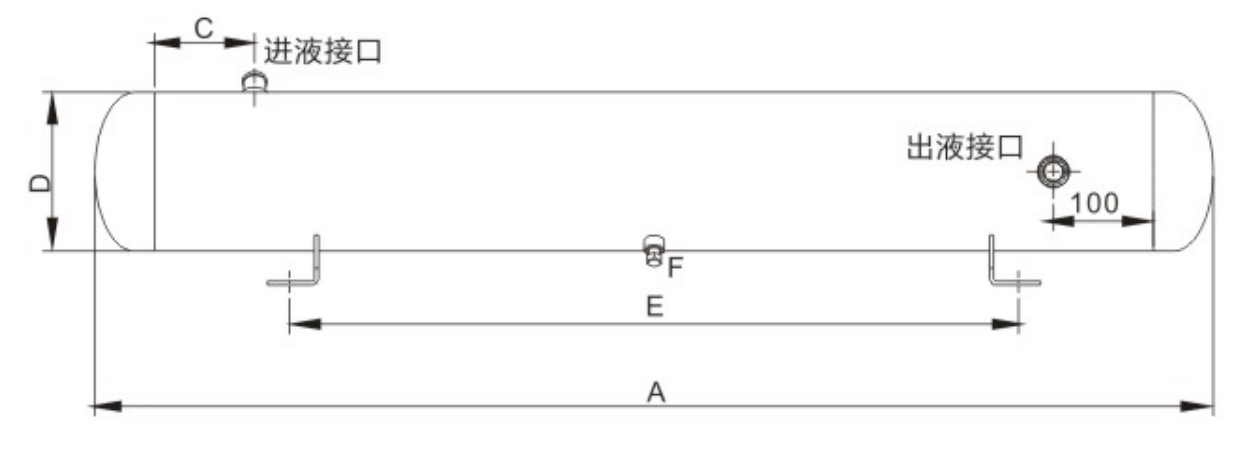

Design: Usually a horizontally placed cylindrical structure, this design helps the natural stratification and separation of the liquid.

Material: Generally made of corrosion-resistant metals such as steel or aluminum to adapt to different refrigerants and operating environments.

Interface: Equipped with multiple interfaces for connecting system components such as condensers, evaporators, filter dryers, etc.

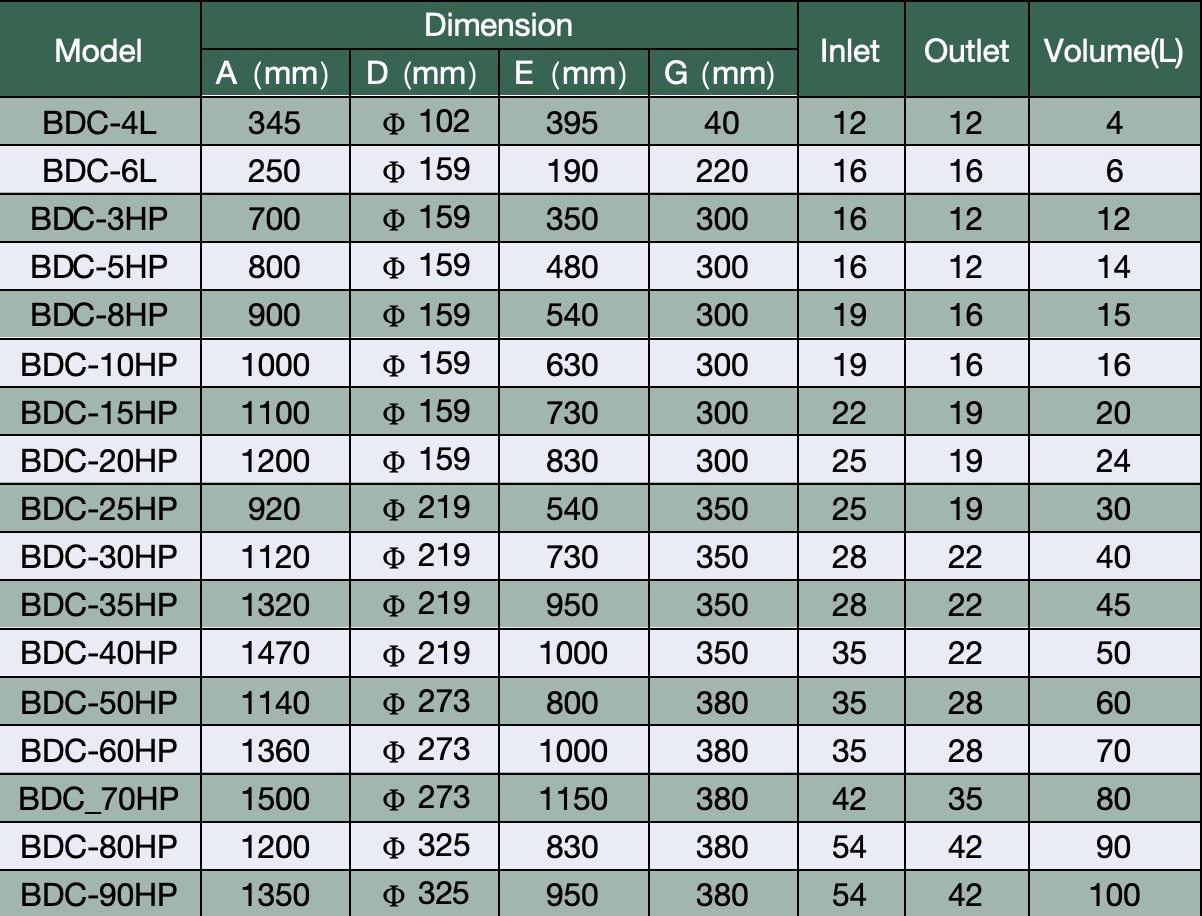

Capacity: There are different capacities and sizes depending on the size and needs of the system.

3. Product Application:

Widely used in commercial and industrial refrigeration systems, such as chillers, cold storage, air conditioning systems, etc.

In systems using liquid refrigerants, liquid receivers are key components to improve system reliability and efficiency.

4. Product Installation:

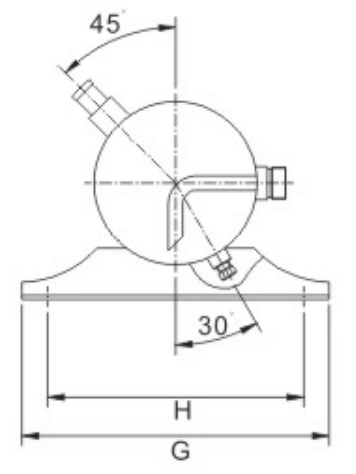

Usually installed after the condenser and before the evaporator to facilitate the storage and distribution of liquid refrigerant.

Proper installation according to the manufacturer's instructions is required to ensure optimal performance and safety.

5. Product Maintenance:

Regularly check the liquid level and refrigerant level to ensure the normal operation of the system.

Clean or replace internal parts as needed to maintain good operating results.